multigateind@gmail.com

Multigate is famous for its client for quality control. Each unit is inspected and checked under the supervision of the best human resources and technologies right from the raw materials to the dispatch. Yet we always follow deadlines in mind. You products not only arrive on time but you don’t have to worry about their quality at all. We aspire you with our quality standard.

Fabric Inspection

Before production begins, all purchased fabric undergoes a thorough quality inspection under specialized lighting to ensure any defects are identified and addressed, preventing issues during manufacturing.

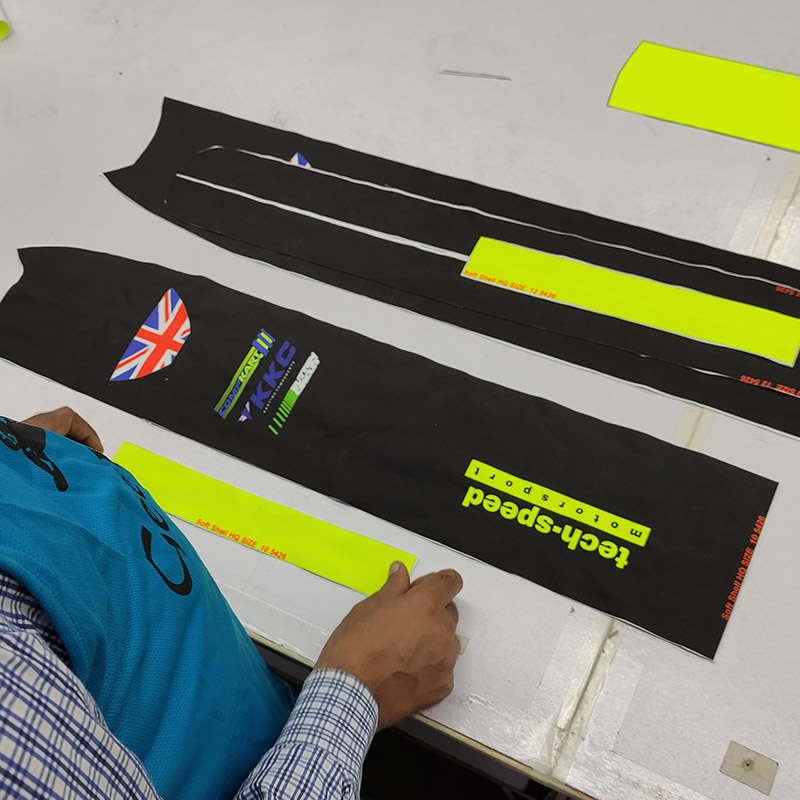

Color Matching

Color matching is the process of blending pigments, dyes, and special effect colors to achieve a precise shade in a specific polymer. This process often includes additives like dispersants and stabilizers to ensure consistency and durability.

RFI Checking

This is a dedicated quality control process where each garment is thoroughly inspected to ensure it meets the specified requirements.

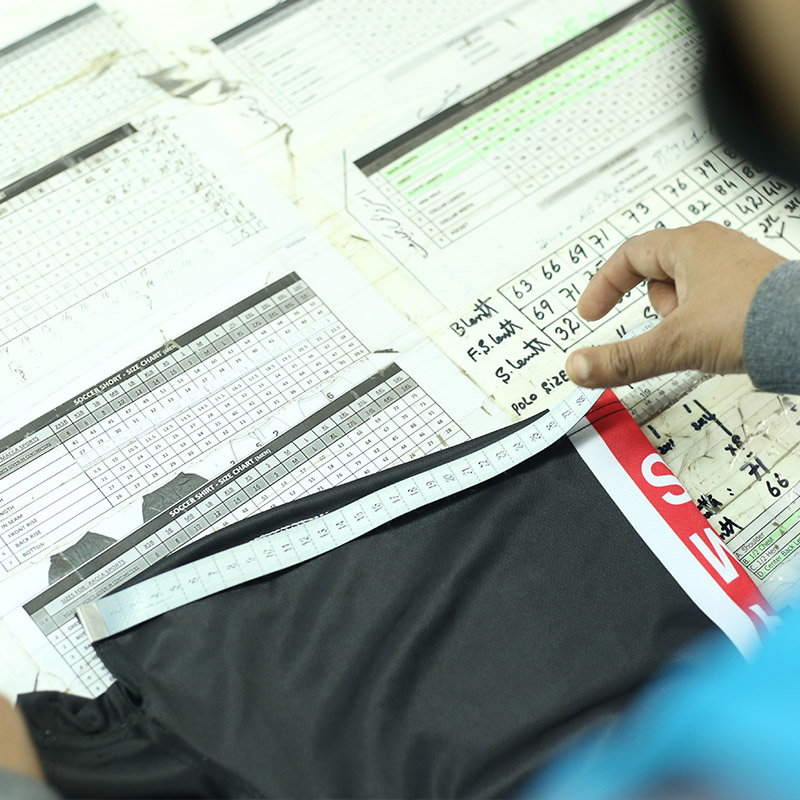

Final Inspection

Final inspection ensures that each garment meets the required standards before tagging and packing. Expert quality checkers assess every unit for accurate measurements, stitching, color consistency, printing quality, and embellishments to guarantee top-notch craftsmanship.

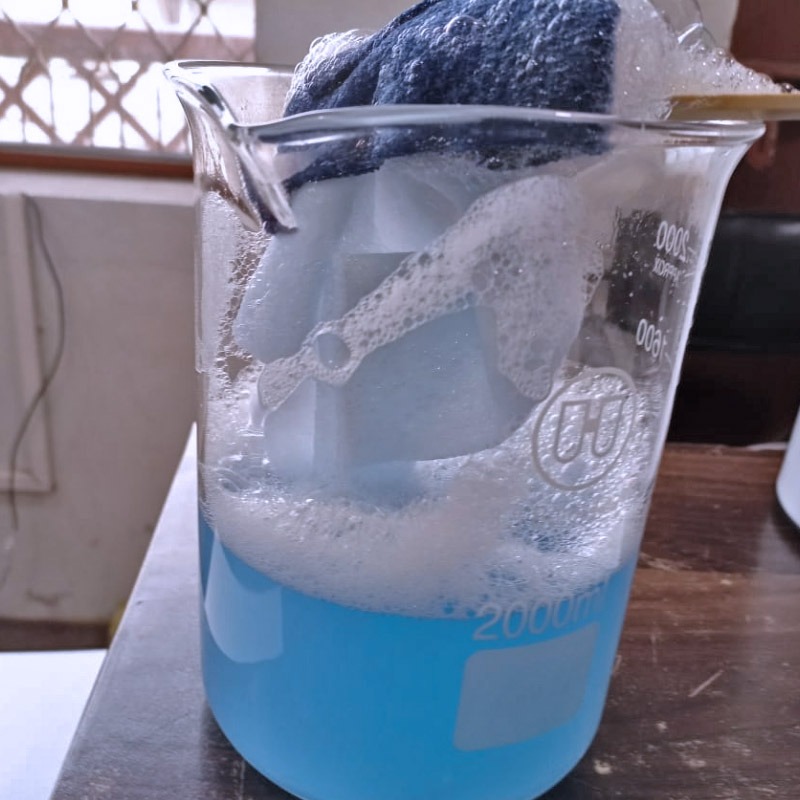

GSM,Bleed & Washing Test

GSM testing is conducted before utilizing the textile, ensuring fabric quality. A mandatory fabric bleed test is performed before proceeding to production. Every fabric lot undergoes thorough testing in the TDP department before being issued for manufacturing. Wash and color bleed tests, including commercial and tumble washes, are conducted to assess colorfastness and durability.